We offer different types of ribbons to suit your unique needs

Our experts will help you choose the right type of thermal transfer ribbon to suit your business & your brand image the best.

Pharmaceutical Drug Labeling

Pharmaceutical Drug Labeling

Thermal transfer printing is used to label drugs & other products with vital data such as dosage details, expiry dates & barcodes.

Barcoding in Logistics

Barcoding in Logistics

Thermal transfer printing is widely used to produce high quality barcodes on labels. This is used to track products & inventory in the logistics sector.

Automotive Parts Identification

Automotive Parts Identification

Due to its durability, it is a perfect fit to label automotive parts with crucial info such as serial no., part no., safety & care details etc.

WAX RIBBONS

Wax ribbons can be used to printing on paper labels & tags

It offers a cost effective solution for general purpose printing & offers a really good printing quality on paper surfaces.

It is mostly used in sectors such as EMS, logistics, healthcare & manufacturing to create quality barcode labels. It is widely used to create high end barcodes on labels to track products & inventory as well as for shipping labels. It is also used to make labels for patient wristbands, drug dose details & lab samples.

WAX RESIN RIBBONS

Wax resin ribbons offer a balance between cost & durability

As it offers a lot of durability, wax resin ribbon is a perfect fit for uses that need fairly less resistance to abrasion, chemicals & exposure to light.

It is used in the EMS, manufacturing, automotive & electronics sector for printing on labels used in automotive parts & other components with vital info such as serial no., part no., & safety details. Wax resin ribbon is ideal for printing on semi gloss or coated paper labels as well as synthetic materials.

RESIN RIBBONS

Resin ribbons offer the highest level of durability & costs the most

As resin ribbon is the most durable ribbon out of all, it is ideal for uses that need to resist harsh conditions like harsh chemicals, high heat & outdoor exposure.

Resin ribbon is the best choice to print on synthetic materials like polyester & polyethylene. As it is highly resistant to harsh chemicals, extreme heat or cold & can withstand other outdoor conditions like humidity, it is mostly used for labels in chemical drums, outdoor signage & medical uses.

WASH CARE RIBBON

Care labels are made exclusively for the textile & apparel industry

In the textile, apparel & garment manufacturing industry, thermal transfer printing is used to create durable care labels with manufacturer details for clothing items & apparels such as shoes, hand bag etc.

Wash care ribbons are specially designed & made to withstand the rigors of the laundry wash process. This ribbon is mostly used to print wash & care instructions and garment details on labels that need to endure repeated washing & ironing.

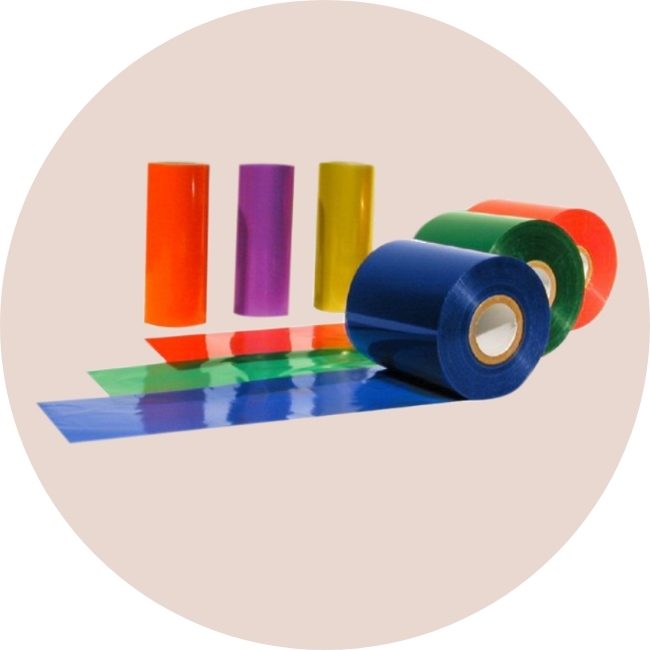

COLOR RIBBON

Color ribbon is used in branding & packaging to boost visual appeal

Color ribbon is used in the product packaging, manufacturing, EMS & branding sector where one needs to convey details in an engaging manner.

Color ribbon is used when it is best to print labels with colored graphics, logos or other brand details to create a brand image. It is used for exclusive uses where visual appeal & brand image boosting is crucial, such as to market & pack products & for EMS labeling as it will help attract consumers.